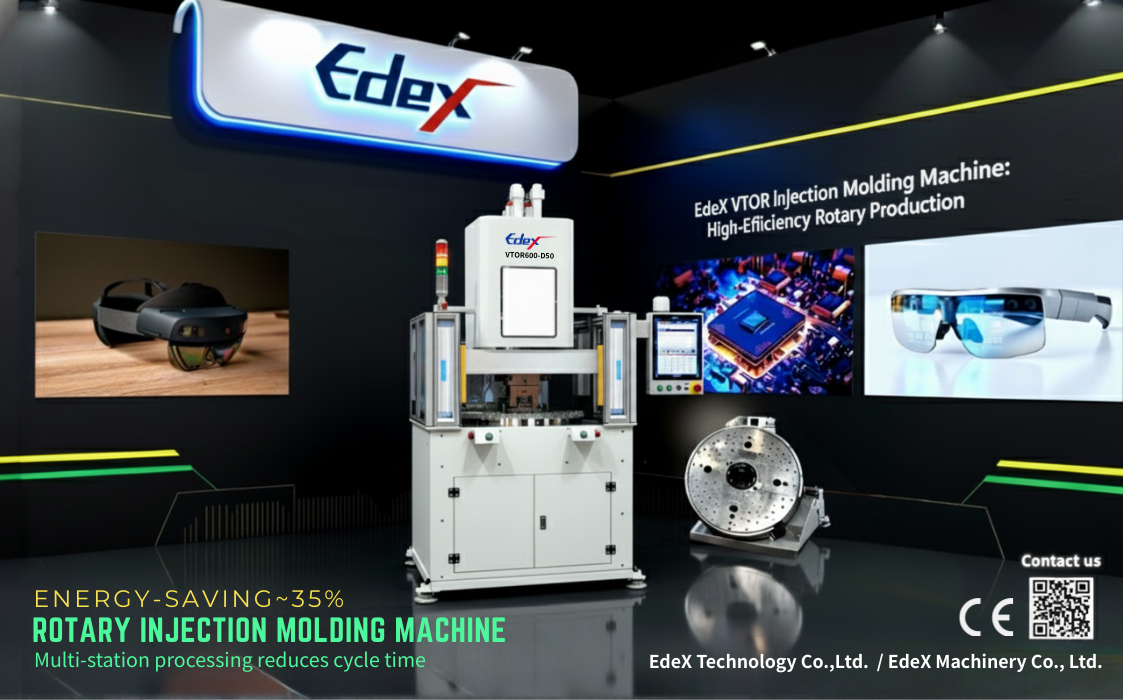

2026 PLASTICO BRASIL Edex VTOR Rotary Machine-35% Energy Saving & High-Precision Molding for the Brazil Market

2026 PLASTICO BRASIL Edex VTOR Rotary Machine -35% Energy Saving & High-Precision Molding for the Brazil Market

Forget the 2026 Booths: The Edex VTOR is Already Winning Brazil's Production War

Let's be honest. Everyone in plastics will be talking about the 2026 Brazil Exhibition, but what are they really going to show? Incremental tweaks? Marginal gains? At Edex, we've skipped the fanfare because the time for "almost good enough" is over, especially for the smart manufacturers in Brazil.

We see the opportunity: high-value products—like those finicky components for AR/VR headsets and the latest Smart Wearable Tech—demand a level of precision and speed that frankly, most machines just can't deliver. If you're running a traditional setup, you're constantly fighting downtime and climbing costs.

The Elephant in the Shop Floor: Idle Time Kills Your Margins

Go look at your shop floor right now. When the machine is cooling the part or the operator is carefully placing a metal insert, what is the expensive injection unit doing? Nothing. Absolutely nothing. That's a huge operational leak.

That's the entire reason we engineered the VTOR Rotary Injection Molding Machine. It's not a tweak; it's a completely restructured workflow designed specifically to eliminate wasted seconds and wasted energy.

✨ VTOR: The Three Non-Negotiable Wins

We built the VTOR to solve three core problems that are hammering profitability in the Brazilian market:

The Time Hack: Real-Time Parallel Processing

Our Precision Rotary Turntable is the key. Imagine this: While one station handles the slow work (cooling, or allowing the operator ample time to load complex electronic inserts), the other station is already busy injecting the next shot. You're no longer waiting for the slowest step. You're running parallel. It's the most effective way to crush your total cycle time.

The 35% Shock: Serious Energy Savings

Let's talk real money. Energy costs aren't dropping anytime soon. Our integrated Servo System and Smart Power Management aren't just greenwashing—they deliver a verifiable reduction of up to 35% in energy consumption compared to the older hydraulic systems. That savings goes directly to your bottom line every day.

Complex Parts Made Simple: Unmatched Versatility

Whether you need smooth overmolding for a comfortable grip or seamless multi-component injection, the stability of our rotary platform handles it. The ability to prepare your inserts at a dedicated, calm station drastically improves yield and reduces scrap on the most difficult parts.

🤝 The Local Edge: Finding Our Anchor in Brazil

We know this technology needs local support. We aren't interested in fly-by-night operations. Edex is looking for established, technically sharp Distributors or Strategic Partners in Brazil—firms that share our intensity and can provide the world-class service this machine deserves.

If you are a serious player ready to represent the future of molding technology and solve real manufacturing problems in the Brazilian market, let's talk.

Don't wait for the exhibition reports. Be the solution. Contact Edex today—we're ready to show you the data.