Exhibitions

TaipeiPLAS 2026 EdeX Advanced Micro-Molding Vertical Injection Technology

EdeX Co., Ltd. at TaipeiPLAS 2026, the premier event for the plastics and rubber industry. We are excited to present our latest innovations at the Taipei Nangang Exhibition Center, Hall 1.

This year, EdeX is highlighting our industry-leading compact vertical injection molding machine.

Engineered with the smallest footprint on the market, our machine is the ideal choice for manufacturers looking to maximize factory floor efficiency while maintaining exceptional precision for complex molding tasks.

Event: TaipeiPLAS 2026 (Taipei International Plastics & Rubber Industry Show)

Date: September 15 – September 19, 2026

Venue: Taipei Nangang Exhibition Center, Hall 1 (TaiNEX 1)

Booth No.: To be announced

Featured Technology:

The World’s Most Compact Design: Maximize your production area.

Precision Engineering: Specialized in micro-molding and vertical insert molding solutions.

We look forward to meeting you at TaipeiPLAS 2026 and discussing how EdeX can optimize your production efficiency.

Autotronics Taipei 2026 Taipei International Automotive Electronics Show

At Autotronics Taipei 2026, EdeX presents comprehensive injection molding solutions designed for automotive electronics and electric vehicle applications, supporting high precision, automation integration, and reliable mass production.

📅 Event Dates:April 14–17, 2026

📍 Venue:Taipei Nangang Exhibition Center Hall 1 , Taipei, Taiwan

EdeX at Taipei Mold & Die Expo 2026: Leading Injection Molding Innovations

As a pioneer in the industry, EdeX is proud to showcase our latest innovations at the Taipei International Mold & Die Industry Fair 2026. We empower manufacturers with high-efficiency and high-precision injection molding technology.

Key Highlights at EdeX Booth:

Precision Performance: Advanced machines designed for micro-molding and complex component production.

Smart Automation: Integrated Industrial 4.0 solutions to enhance production transparency and yield.

Eco-Friendly Solutions: Energy-saving technologies that support sustainable manufacturing goals.

Exhibition Details:

Date: August 19~22, 2026 Time: 9:30~17:00

Venue: Taipei Nangang Exhibition Center, Hall 2,4F

Booth No.: Coming Soon

Featured Products: Precision Injection Molding Machines, Robotic Systems, Smart Factory Solutions.

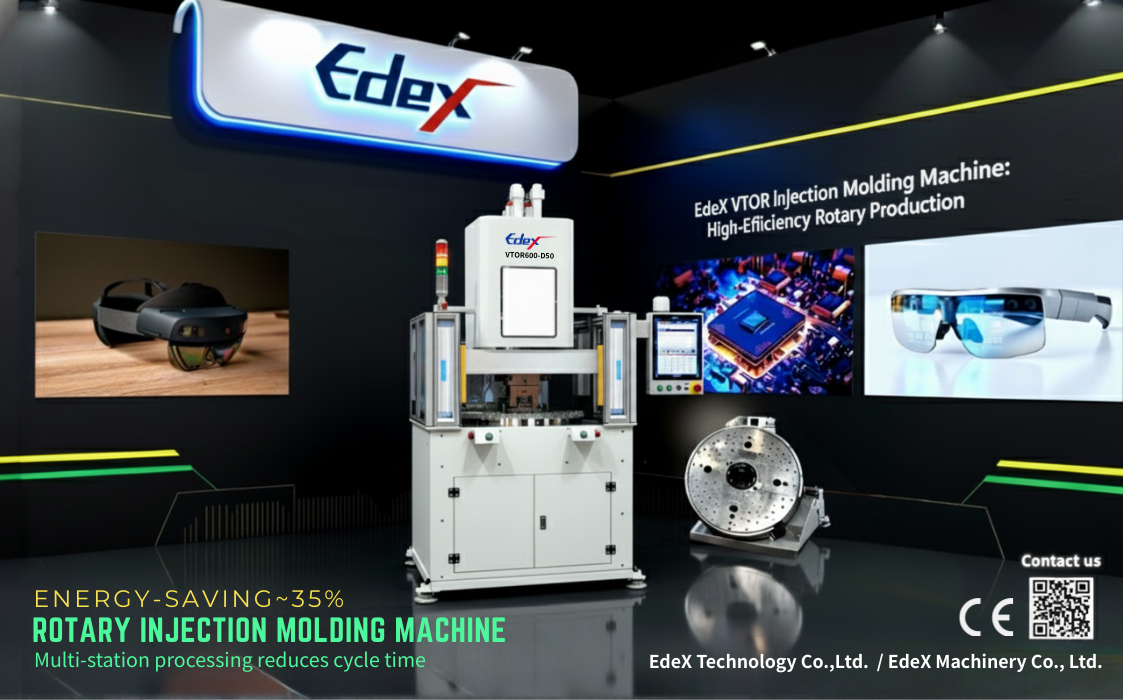

2026 PLASTICO BRASIL Edex VTOR Rotary Machine-35% Energy Saving & High-Precision Molding for the Brazil Market

Let's be honest. Everyone in plastics will be talking about the 2026 Brazil Exhibition, but what are they really going to show? Incremental tweaks? Marginal gains? At Edex, we've skipped the fanfare because the time for "almost good enough" is over, especially for the smart manufacturers in Brazil.

We see the opportunity: high-value products—like those finicky components for AR/VR headsets and the latest Smart Wearable Tech—demand a level of precision and speed that frankly, most machines just can't deliver. If you're running a traditional setup, you're constantly fighting downtime and climbing costs.

The Elephant in the Shop Floor: Idle Time Kills Your Margins

Go look at your shop floor right now. When the machine is cooling the part or the operator is carefully placing a metal insert, what is the expensive injection unit doing? Nothing. Absolutely nothing. That's a huge operational leak.

That's the entire reason we engineered the VTOR Rotary Injection Molding Machine. It's not a tweak; it's a completely restructured workflow designed specifically to eliminate wasted seconds and wasted energy.

✨ VTOR: The Three Non-Negotiable Wins

We built the VTOR to solve three core problems that are hammering profitability in the Brazilian market:

The Time Hack: Real-Time Parallel Processing

Our Precision Rotary Turntable is the key. Imagine this: While one station handles the slow work (cooling, or allowing the operator ample time to load complex electronic inserts), the other station is already busy injecting the next shot. You're no longer waiting for the slowest step. You're running parallel. It's the most effective way to crush your total cycle time.

The 35% Shock: Serious Energy Savings

Let's talk real money. Energy costs aren't dropping anytime soon. Our integrated Servo System and Smart Power Management aren't just greenwashing—they deliver a verifiable reduction of up to 35% in energy consumption compared to the older hydraulic systems. That savings goes directly to your bottom line every day.

Complex Parts Made Simple: Unmatched Versatility

Whether you need smooth overmolding for a comfortable grip or seamless multi-component injection, the stability of our rotary platform handles it. The ability to prepare your inserts at a dedicated, calm station drastically improves yield and reduces scrap on the most difficult parts.

🤝 The Local Edge: Finding Our Anchor in Brazil

We know this technology needs local support. We aren't interested in fly-by-night operations. Edex is looking for established, technically sharp Distributors or Strategic Partners in Brazil—firms that share our intensity and can provide the world-class service this machine deserves.

If you are a serious player ready to represent the future of molding technology and solve real manufacturing problems in the Brazilian market, let's talk.

Don't wait for the exhibition reports. Be the solution. Contact Edex today—we're ready to show you the data.

[Link to your Contact Page / Partnership Inquiry Form for the Brazil Market]

Argenplas 2026 – Market Insights & Vertical Injection Molding Solutions from EdeX Taiwan

Argenplas 2026 highlights the rising demand and strong development momentum within Argentina’s plastics and rubber sector. EdeX will continue supporting South American manufacturers with advanced vertical injection molding technologies, helping them enhance quality, productivity, and operational efficiency.

EdeX at TPCA 2025|EP Low-Pressure Machine & AI Smart Glasses Highlights|Booth N102

We sincerely invite global customers to visit us at TPCA 2025 to experience our EP Low-Pressure and PCBA Injection Molding Machines, and explore the future of AI smart manufacturing.

You're Invited: Discover the VE Series at TAIMOLD 2025!

Dear Partners and Industry Professionals,

Edex Technology sincerely invites you and your team to visit our booth at TAIMOLD 2025 this August in Taipei. At the show, we will be showcasing our latest VE Series Vertical Injection Molding Machines, designed for high-precision insert molding with compact, energy-saving, and smart control features.

With decades of experience in vertical injection technology, Edex offers tailor-made solutions for applications in electronics, automotive, medical, and more. The VE Series features digital back pressure control, high-speed injection units, and rotary table options, providing superior stability, safety, and space efficiency.

Don't miss this opportunity to experience live demonstrations and explore how Edex can boost your manufacturing performance.

Booth: S303

Date: August 20–23, 2025

Venue: Nangang Exhibition Center Hall 2, 4F, Taipei

If you have any questions or need assistance before the show, feel free to contact us.

We look forward to seeing you at the exhibition!

Warm regards,

Edex Technology Co., Ltd.

www.edex-injection.com